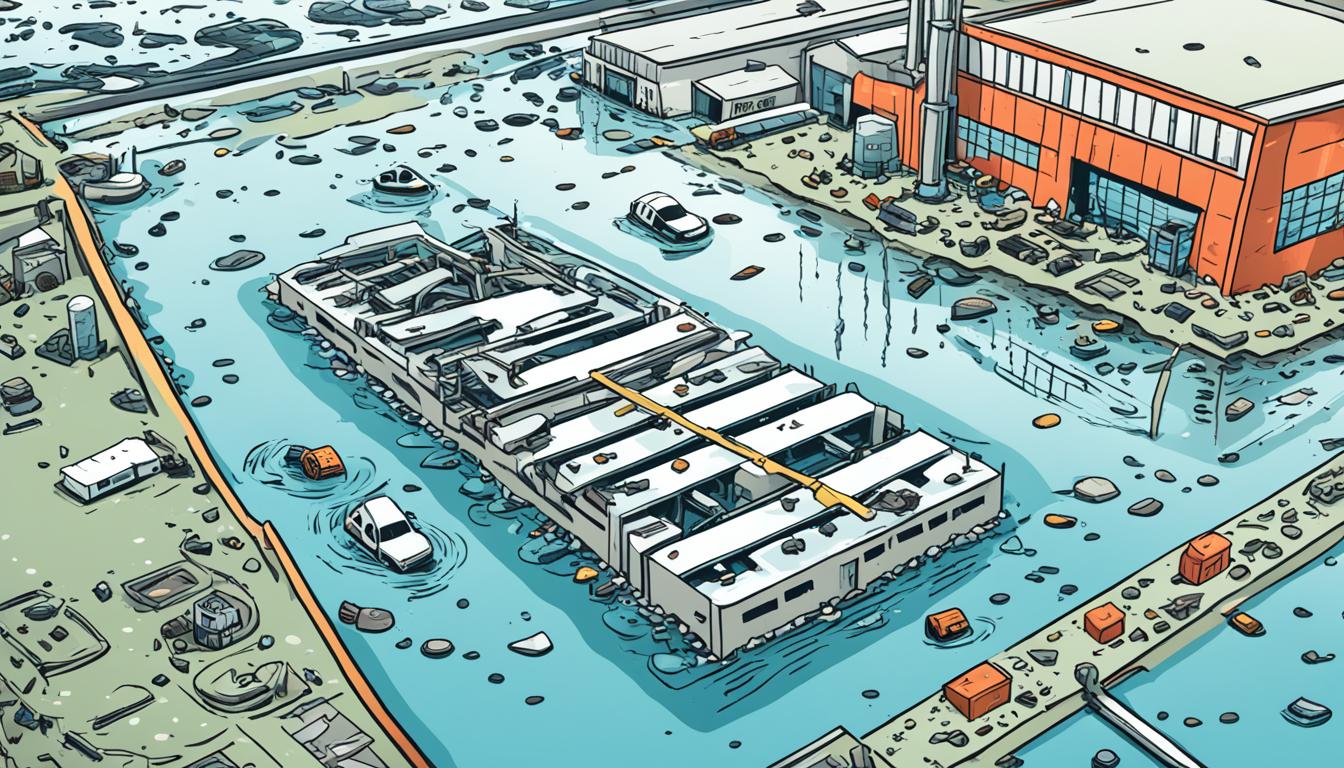

Natural disasters have the potential to cause significant disruptions in global supply chains, leading to negative impacts on the economy. The effects of natural disasters can be far-reaching and can result in the breakdown of communication, supplier shortages, production halts, disrupted transportation, imbalances in inventory, increased lead times and costs. It is crucial for organizations to understand these challenges and implement strategies to mitigate the impact of natural disasters on their supply chains.

Key Takeaways:

- Natural disasters can disrupt global supply chains, causing negative impacts on the economy.

- Disruptions can include communication breakdowns, supplier shortages, production halts, and disrupted transportation.

- Organizations must implement strategies to mitigate the impact of natural disasters on their supply chains.

- Understanding the challenges and developing contingency plans are crucial for supply chain management.

- Investing in resilience and building strong partnerships within the supply chain can help navigate through challenging times.

The Impact of Natural Disasters on Supply Chains

Natural disasters can have a profound economic impact on global supply chains. Major disasters disrupt economies beyond the scope of local damage, as the effects trickle through the supply chains, causing uncertainty and chaos.

Recent examples include the Tohoku Earthquake and Tsunami in Japan in 2011, which cost the country an estimated $210 billion and led to disruptions in global production. The flooding in Thailand in the same year also had a significant impact on the computer industry’s supply chains.

These examples highlight the need for organizations to be prepared for the potential impact of natural disasters on their supply chains.

In order to illustrate the impact of natural disasters on supply chains, consider the following data:

| Event | Location | Economic Impact | Disrupted Industries |

|---|---|---|---|

| Tohoku Earthquake and Tsunami | Japan, 2011 | $210 billion | Global production |

| Flooding in Thailand | Thailand, 2011 | Significant impact | Computer industry |

As shown in the table above, natural disasters can result in massive economic losses and disrupt industries on a global scale. Organizations must recognize the potential risks and take proactive measures to ensure the resilience and continuity of their supply chains.

In the next section, we will discuss contingency and emergency planning, and what organizations need to know to effectively prepare for natural disasters.

Contingency and Emergency Planning – What You Need to Know

An effective business continuity management plan is essential in preparing for natural disasters and emergencies. By implementing a well-designed contingency plan, organizations can minimize the impact of these events on their supply chains.

Consulting Stakeholders and Evaluating Risks

A crucial first step in contingency planning is consulting stakeholders, including suppliers, partners, and internal teams. This collaborative approach ensures that all perspectives are considered, and valuable insights are incorporated into the plan. Additionally, organizations must evaluate the specific risks associated with natural disasters and emergencies that may affect their supply chain.

Building Redundancy and Resilience

Building redundancy and resilience into the supply chain is another key aspect of contingency planning. This involves identifying critical suppliers, establishing backup options, and diversifying sourcing locations. By creating redundancies, organizations can mitigate the impact of disruptions caused by natural disasters.

Considering Risks at All Supply Chain Locations

Contingency planning should account for risks at all supply chain locations. This includes assessing the vulnerabilities of manufacturing facilities, warehouses, transportation routes, and distribution centers. By evaluating potential weak points in the supply chain, organizations can develop strategies to address and mitigate these risks.

Documenting the Contingency Plan

A well-documented contingency plan is crucial for its effective implementation. This plan should outline the specific actions to be taken in the event of a natural disaster or emergency, as well as the roles and responsibilities of each team member involved. By documenting the plan, organizations ensure that everyone is clear on their responsibilities and can respond swiftly and effectively when needed.

Consideration of Downstream Effects on Customers

Contingency planning should also take into account the downstream effects on customers. This includes considering potential price changes, product availability, and communication channels during a disruption. By proactively addressing these effects, organizations can maintain customer satisfaction and minimize the long-term impact on their business.

Overall, contingency planning and emergency preparedness are essential for organizations to mitigate the impact of natural disasters on their supply chains. By consulting stakeholders, evaluating risks, building redundancy and resilience, considering risks at all locations, documenting the contingency plan, and considering downstream effects on customers, organizations can be well-prepared and effectively respond to disruptions.

4 Steps to Dealing with Disaster

When faced with a natural disaster, organizations should follow these four steps to effectively deal with the situation.

1. Be Organized: Creating a detailed documentation and guidelines for the supply chain emergency operations plan is crucial. This ensures that everyone in the organization is aware of their roles and responsibilities during a crisis. Having a well-defined plan in place helps in maintaining stability and minimizing disruptions.

2. Transparency is Key: Open and clear communication with suppliers, partners, and internal staff is vital during a disaster. Providing updates and sharing relevant information helps in managing expectations and maintaining trust. Transparency enables better collaboration and coordination, ensuring smooth operations even in challenging circumstances.

3. Building Strong Partnerships: Establishing strong partnerships within the supply chain is essential for navigating through challenging times. Collaborating with key stakeholders and working collaboratively to address issues and find solutions can help in minimizing the impact of a disaster on the supply chain. By building strong relationships, organizations can leverage each other’s strengths and resources to overcome challenges together.

4. Agility and Adaptability: Organizations should be prepared to adjust plans and operations as needed during a disaster. The recovery process is often fluid, and flexibility is crucial in responding to changing circumstances. By being agile and adaptable, organizations can quickly recover and resume operations, minimizing the overall impact of the disaster.

Analyze, adapt, and act: Effective disaster response requires agility and adaptability.

Example Table:

| Step | Description |

|---|---|

| 1 | Create a supply chain emergency operations plan |

| 2 | Communicate transparently with suppliers, partners, and internal staff |

| 3 | Build strong partnerships within the supply chain |

| 4 | Be agile and adaptable in adjusting plans and operations |

By following these four steps, organizations can effectively deal with disasters and mitigate the impact on their supply chains. It is crucial to have a robust plan, transparent communication, strong partnerships, and the ability to adapt quickly to emerging challenges. With the right strategies in place, organizations can minimize disruptions and recover more efficiently.

Kettering Online’s Innovative Master’s Degree in Supply Chain Management

Kettering University offers a Master of Science in Supply Chain Management program designed to equip students with the knowledge and skills necessary to excel in the field of supply chain management. This innovative program combines traditional approaches with the latest industry trends, providing students with a comprehensive understanding of supply chain dynamics in today’s global market.

Through a practical framework focusing on the foundations of supply chain management, financial management, and logistics, students gain valuable insights into the complexities and challenges of managing supply chains. The program’s curriculum is carefully designed to prepare students for real-world scenarios, including potential disruptions caused by natural disasters.

By enrolling in Kettering’s Master’s Degree in Supply Chain Management, students have the opportunity to learn from experienced industry professionals and cutting-edge research. The program emphasizes hands-on learning, with case studies, simulations, and collaborative projects that allow students to apply their knowledge in practical situations.

Graduates of the program emerge as highly skilled professionals ready to tackle the challenges of supply chain management with confidence and expertise. With a deep understanding of supply chain dynamics and the ability to navigate through potential disruptions, they are well-positioned to make strategic decisions that drive business success.

Whether aspiring to advance in their current roles or seeking new opportunities in the field of supply chain management, Kettering’s Master’s Degree in Supply Chain Management provides graduates with a competitive edge in the job market. They are equipped with the knowledge, skills, and industry connections to excel in a rapidly evolving global marketplace.

Challenges Arising from Disruptions

Disruptions caused by natural disasters can significantly impact supply chain management, leading to various challenges that organizations must navigate. These challenges include:

- Breakdown in Communication and Visibility: Natural disasters can result in a breakdown in communication channels, making it difficult for stakeholders to coordinate and share critical information. This lack of visibility can hinder decision-making and slow down response times.

- Supplier Shortages and Production Halts: When a natural disaster strikes, suppliers may experience disruptions in their operations, leading to shortages in the availability of raw materials or finished goods. Production halts can further exacerbate the supply chain disruptions, causing delays and impacting customer satisfaction.

- Disrupted Transportation and Logistics: Natural disasters can damage transportation infrastructure, including roads, bridges, and ports. This disruption can impede the movement of goods and increase transportation costs, leading to delays and logistical challenges.

- Inventory Imbalances: Supply chain disruptions can result in imbalances in inventory levels. Some organizations may face excess inventory due to disruptions in demand, while others may experience shortages due to supplier disruptions. These imbalances can impact profitability and customer satisfaction.

- Increased Lead Times and Costs: Supply chain disruptions can lead to increased lead times for the delivery of goods and services. Lengthier lead times can impact customer satisfaction and increase costs due to expedited shipping or alternative sourcing.

To overcome these challenges, organizations must proactively develop strategies and plans to mitigate the impact of supply chain disruptions caused by natural disasters. By implementing robust contingency plans, establishing strong communication channels, diversifying suppliers, and monitoring inventory levels, organizations can maintain resilience in the face of disruptions.

| Challenges Arising from Disruptions | Solutions |

|---|---|

| Breakdown in Communication and Visibility | Implement clear communication protocols and utilize technology to enhance visibility across the supply chain. |

| Supplier Shortages and Production Halts | Diversify supplier base, establish strong relationships, and implement contingency plans to address production disruptions. |

| Disrupted Transportation and Logistics | Develop alternative transportation routes, strengthen relationships with logistics providers, and assess the impact of disruptions on transportation networks. |

| Inventory Imbalances | Implement demand forecasting and inventory management strategies to optimize inventory levels and respond to disruptions. |

| Increased Lead Times and Costs | Optimize supply chain networks, explore alternative sourcing options, and enhance supply chain agility to mitigate the impact of increased lead times and costs. |

By addressing these challenges and implementing proactive strategies, organizations can minimize the impact of supply chain disruptions caused by natural disasters, ensuring the continuity of their operations and mitigating financial losses.

Solutions to Mitigate Supply Chain Disruptions

To mitigate the impact of supply chain disruptions caused by natural disasters, organizations can implement several solutions. These strategies are designed to enhance resilience and minimize the effects of unexpected events on supply chain operations. By adopting a proactive approach to risk management and implementing the following measures, organizations can better prepare for and respond to supply chain disruptions.

Risk Assessment and Planning

Conducting comprehensive risk assessments is crucial to identify potential vulnerabilities in the supply chain. By assessing the likelihood and potential impact of natural disasters, organizations can prioritize their risk mitigation efforts. This includes identifying alternative suppliers and transportation routes, developing contingency plans, and establishing clear protocols for response and recovery.

Real-time Monitoring and Analytics

Implementing real-time monitoring and analytics tools allows organizations to gain insight into their supply chain operations and detect potential disruptions in advance. By leveraging data and analytics, organizations can proactively identify and address issues before they escalate and impact the entire supply chain. Real-time monitoring enables quick decision-making and allows organizations to quickly adapt their operations to minimize the impact of disruptions.

Supplier Collaboration and Relationships

Fostering strong relationships with suppliers and promoting collaboration is essential in mitigating supply chain disruptions. Regular communication and collaboration initiatives ensure transparent information sharing and enable early detection of potential risks. Establishing a collaborative partnership with suppliers can also facilitate access to alternative resources and backup plans, enabling organizations to quickly recover from disruptions.

Diversification and Redundancy

Organizations can reduce their vulnerability to supply chain disruptions by diversifying their supplier base and establishing redundant systems. By maintaining relationships with multiple suppliers and having backup plans in place, organizations can minimize the impact of disruptions on their supply chains. This includes identifying alternative sources for critical components or materials and establishing redundant production or storage facilities in geographically separate locations.

Agile and Flexible Operations

Building agile and flexible operations allows organizations to quickly adapt to changing circumstances and minimize the impact of disruptions. This includes implementing agile manufacturing practices, such as modular production systems and flexible workforce arrangements, that enable rapid adjustments in response to disruptions. By embracing flexibility in operations, organizations can maintain continuity and meet customer demands, even in the face of unexpected events.

Investment in Resilience

Investing in resilience involves allocating resources to strengthen the supply chain’s ability to withstand disruptions. This may include investing in advanced technologies, such as predictive analytics and automation, that enhance visibility and responsiveness. Additionally, organizations can invest in training and developing their workforce to improve their ability to manage disruptions effectively.

By adopting these solutions, organizations can mitigate the impact of supply chain disruptions caused by natural disasters. Taking a proactive approach to risk management, fostering collaboration and relationships, diversifying suppliers, implementing agile operations, and investing in resilience are key strategies in ensuring supply chain continuity and minimizing the effects of unpredictable events.

Conclusion

Natural disasters can have a devastating impact on supply chains, leading to disruptions in communication, shortages of suppliers, halts in production, transportation breakdowns, imbalances in inventory, and increased lead times and costs. However, organizations can minimize these challenges by implementing strategic solutions to mitigate the effects of natural disasters.

By conducting risk assessments and contingency planning, organizations can better prepare for potential disruptions. Real-time monitoring and analytics enable businesses to proactively identify and respond to supply chain disruptions caused by natural disasters. Building strong supplier collaboration and relationships can help maintain continuity during challenging times.

Additionally, organizations can develop agile and flexible operations to quickly adapt their supply chains to unforeseen circumstances. Diversifying suppliers and investing in redundancy can reduce dependency on single sources and increase resilience. Lastly, organizations should focus on investing in resilience measures to ensure the continuity of their operations, even in the face of natural disasters.